Pressure Tests

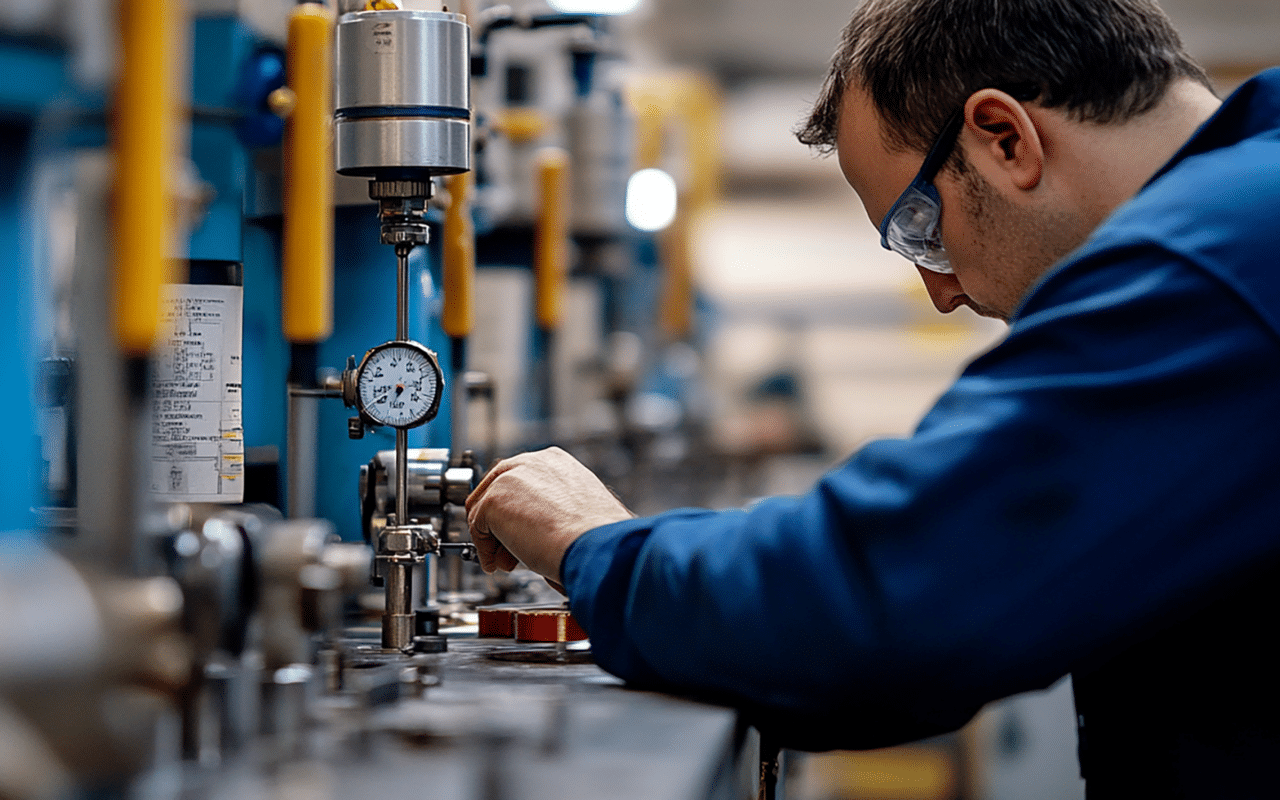

Shell Test:

o Involves subjecting the entire valve body to hydrostatic or pneumatic pressure.

o Typically performed at 1.5 times the valve's rated pressure.

o Aims to verify the structural integrity of the valve body.

Seat Test:

o Focuses on the sealing surfaces of the valve.

o Involves applying hydrostatic or pneumatic pressure to the closed valve.

o Checks for leakage across the valve seat.

Functional Tests

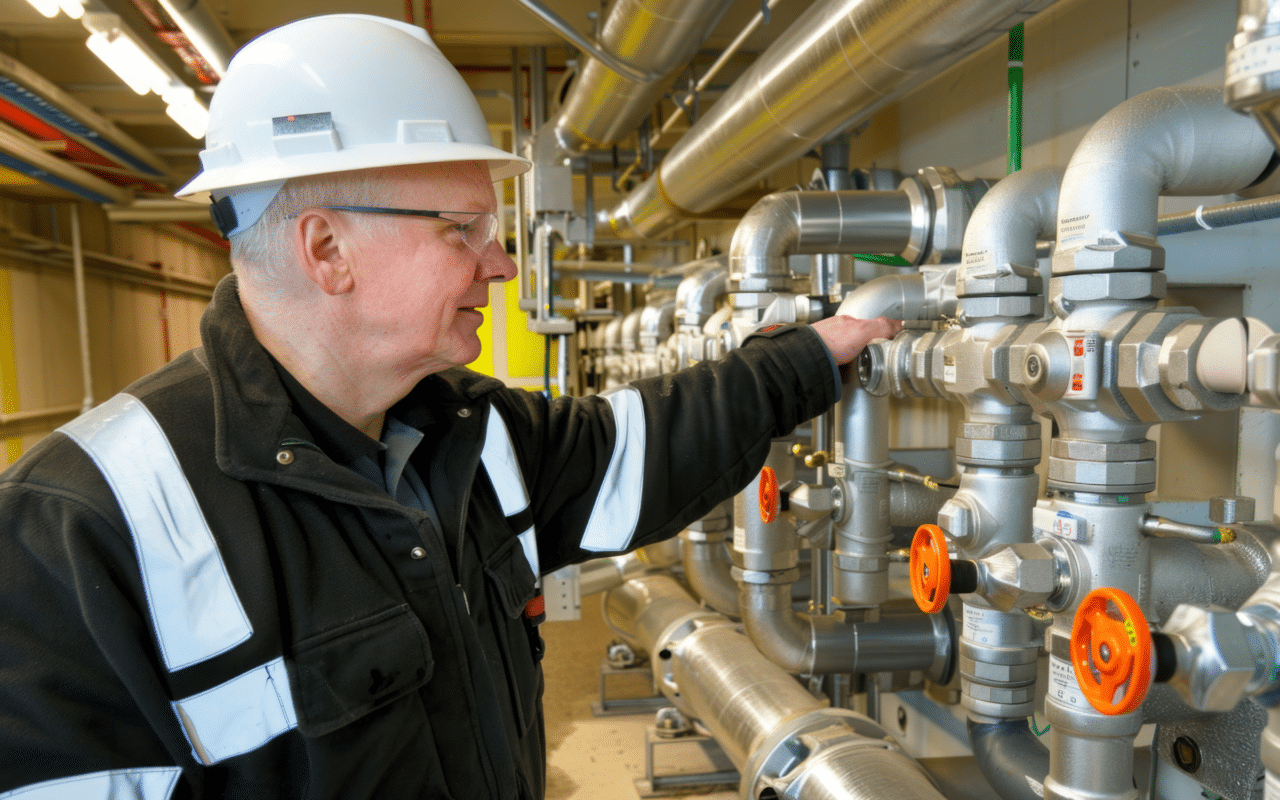

Operation Test:

o Evaluate the valve's ability to open and close fully and smoothly.

o Includes checking for stiction, binding, or excessive torque.

Leakage Test:

o Determines the leakage rate through the valve seat, stem, and packing.

o It can be performed using various methods, including bubble testing, helium mass spectrometry, or pressure decay.

o Includes cavity valve test (CVT).