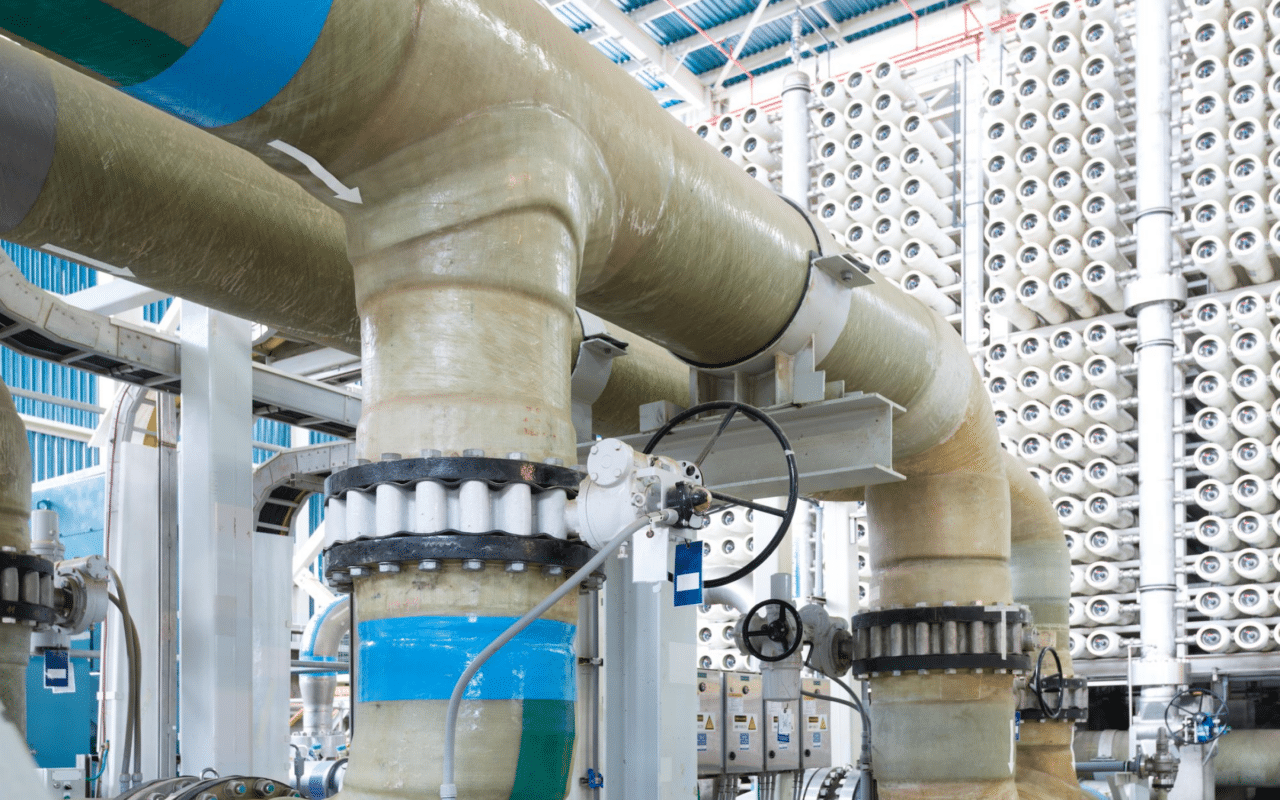

Preservation of static equipment is critical to the safe and efficient operation of refineries, This involves taking steps to prevent corrosion, damage, and deterioration of equipment that is not in use

We begin with a detailed assessment of the equipment, understanding its specific preservation needs based on factors such as type, material, and intended duration of storage or inactivity

Development of customized preservation plans that outline the necessary steps, materials, and techniques required to protect the equipment

Application of protective coatings and corrosion inhibitors to prevent rust and

degradation, particularly for metal components

Use of specialized wraps and sealants to shield equipment from environmental factors like humidity, salt air, and extreme temperatures

Implementation of humidity and temperature control measures within storage environments to prevent moisture build-up and material degradation

Use of desiccants, dehumidifiers, and vacuum-sealed packaging to maintain optimal conditions for sensitive equipment

Regular rotation and lubrication of moving parts to prevent seizing and wear during periods of inactivity

Filling of equipment systems with protective fluids or inert gases to prevent corrosion and contamination